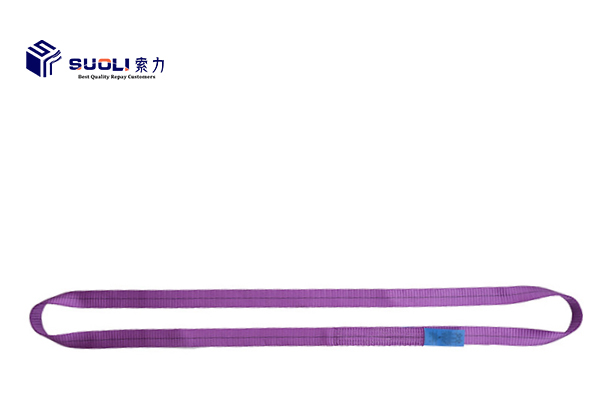

Our company can make single, multi-layer, four-layer flat ring sling according to customer's needs, they are made of polyester, nylon and polypropylene one of the raw materials, our company can provide a 6:1 safety factor of various products. The products meet the international standard ISO9001 safety requirements, customers can order special length products according to their own needs. Flat sling is light, soft, high safety factor, long service life, non-conductive, no danger of electric shock, good resistance to corrosion and other advantages, is gradually replacing steel wire rope and chain rigging.

Webbing Slings supplier can be divided into single layer, double layer and four layer, and the stitching method is various, the size can be customized according to the user's requirements (1-50 tons load, length range 1-100 meters), bearing surface width, can reduce the pressure of surface load; Flat sling outer surface smooth and fine objects, will not harm the hanging objects, can be added anti-wear protective sleeve and anti-cutting protective sleeve, safety factor ratio of 6:1; Flat sling has a unique label, and the use of international standard color to distinguish the bearing tonnage, even if the sling is damaged, it is easy to identify, the surface can be hardened by PU, enhance wear resistance, light and soft, easy to use in a narrow space;

Product advantages:

1, light weight, easy to use, wide bearing surface, can reduce the pressure of surface load

2. No damage to the surface of the hanging object

3, lifting smooth, safe

4, strong and high, bright color

5. Improve labor efficiency and save costs

6. Good corrosion resistance and wear resistance

7, wide use: used in ports and docks, chemical, steel, machinery, installation and other industrial fields

Matters needing attention:

1, do not use the damaged sling

2. Do not twist or wring the sling when lifting

3, do not let the sling knot

4. Avoid tearing sewing joints or overload work

5. When moving the sling, do not drag it

6, avoid grabbing or shock load

7. Every sling must be inspected before every use

8, tapefiber has the function of resistance to inorganic acid, but vulnerable to organic acid damage

9. Polypropylene is suitable for use in places that are most resistant to chemical substances

10, nylon has the ability to resist inorganic acid, vulnerable to organic acid damage

11, nylon in moisture, strength loss can reach 1 5%

12. Seek advice from the supplier if the sling is to be used in situations where it is likely to be contaminated with chemicals or at high temperatures.

Product features:

Webbing Slings supplier adopts high-quality synthetic fiber as raw material, utilizes advanced weaving technology and equipment, and is sewn by different stitching methods. According to customer requirements, Webbing Slings supplier with 4, 5, 6, 7, 8 times safety factor can be made, and the production range is 0.5T-100T. International standard colors are used to identify different carrying capacities, and bandwidth can also be used to distinguish. During lifting operation, it will not cause damage to the surface of the object to be lifted.

According to different lifting environment requirements, it can be divided into: common type, fireproof type, fluorescent type, high strength type, acid resistant type, wear-resistant type, oil-proof waterproof type and other product series.

Features: light, soft, high safety factor, long service life, non-conductive, anti-corrosion, anti-static.

Post time: May-25-2022